Infrastructure & Laboratories

Lab Name: Transportation Engineering

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

90sqm |

| 2 |

Lab In charge |

Prof.Patil S.M. |

| 3 |

Lab Technician |

- |

| 4 |

Lab Investment |

2,63,330 |

| 5 |

List of major equipments |

- Los Angeles Abrasion testing machine

- Marshall Stability Apparatus

- Ductility Apparatus

- Softening Point Apparatus

- Flash and Fire Tester

- Centrifugal Extractor

|

| 6 |

List of Software’s |

|

| 7 |

Practical’s Conducted in Laboratory |

I. Tests on Aggregate:

- Aggregate Impact Value Test

- Aggregate Crushing Strength Test

- Los Angeles Abrasion Test

- Shape Test (Flakiness Index and Elongation Index)

- Specific Gravity and Water Absorption Test by basket method

- Stripping Value Test

- Soundness Test

II. Tests on Bitumen:

- Penetration Test

- Ductility Test

- Softening Point Test

- Flash Point & Fire Point Test

- Bitumen Extraction Test (compulsory)

- Viscosity Test (Tar Viscometer)

- Specific Gravity Test

III. Tests on Aggregate Bitumen Combined:

|

Lab Name: Geotechnical Engineering

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

90sqm |

| 2 |

Lab In charge |

Prof. Jagtap K. M. |

| 3 |

Lab Technician |

|

| 4 |

Lab Investment |

5,27,625 |

| 5 |

List of major equipments |

- Tri-axial shear test Apparatu

- Unconfined Compression test Apparatus

- Direct shear test Apparatus

|

| 6 |

List of Software’s |

|

| 7 |

Practical’s Conducted in Laboratorys |

- Water content determination by any two methods a) Oven drying method, b) Infrared moisture method, c) calcium carbide method

- Specific gravity determination by Pycnometer /density bottle.

- Sieve analysis, particle size determination and IS classification as per I.S. Codes.

- Determination of Consistency limits and their use in soil classification as per I.S. Codes.

- Field density test by a) Core cutter b) Sand Replacement and c) Clod method

- Determination of coefficient of permeability by a) Constant head and b) Variable head method.

- Direct shear test.

- Unconfined compression test.

- Vane Shear test.

- Triaxial test

- Standard Proctor test / Modified Proctor test.

- Differential free swell test.

- Swelling Pressure test

|

Lab Name: Testing Of Material

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

90sqm |

| 2 |

Lab In charge |

Prof. Itape S.B. |

| 3 |

Lab Technician |

|

| 4 |

Lab Investment |

7,44,025 |

| 5 |

List of major equipments |

- Compression Testing Machine

- Vibrating Table

- Aggregate Impact Testing Machine

- Concrete Pan Mixer

- Flow Table

- Vee Bee Consistomer

- Compaction factor Apparatus

- Rebound Hammer

|

| 6 |

List of Software’s |

|

| 7 |

Practical’s Conducted in Laboratory |

A] Cement

- Fineness of cement and fly ash (by sieve method)

- Standard consistency Initial and final setting time and Soundness of cement.

- Compressive strength of cement

B] Filler Materials ( Fine & coarse aggregate)

- Fineness modulus, Moisture content, silt content, bulk density and specific gravity of fine and coarse aggregate.

C] Concrete

- Workability of concrete with and without admixture by slump cone, compaction factor, and or Vee-Bee Consistometer apparatus.

- Compressive strength test of concrete on cubes by destructive and non-destructive method rebound Hammer

- Compressive strength test of concrete on cylinder

- Indirect tensile strength and flexural strength of hardened concrete.

Metals

- Tension test on mild and TMT steel.

- Shear (Single & Double) test on mild steel

- Torsion test on mild steel.

- Impact (Izod & Charpy) test on mild steel, aluminum, brass.

Timber & Ply wood

- Compression test on timber (Parallel & Perpendicular)

- Bending test on timber and plywood

Bricks & Tiles

- Field tests on bricks

- Water absorption test on bricks.

- Efflorescence test on bricks.

- Compressive strength test on bricks

- Flexural strength of flooring tiles.

- Abrasion test of flooring tiles.

|

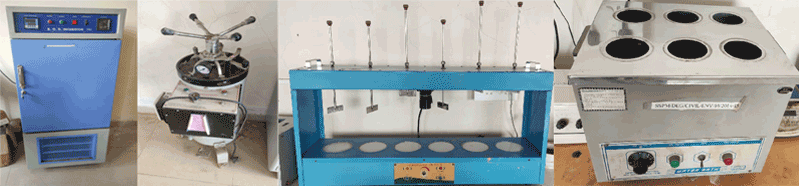

Lab Name: Environmental Engineering Lab

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

90sqm |

| 2 |

Lab In charge |

Prof Khatal J.M. |

| 3 |

Lab Technician |

|

| 4 |

Lab Investment |

2,58,980 |

| 5 |

List of major equipments |

- B.O.D. Incubator,

- C.O.D. Digestion Apparatus

- Jar test apparatus

- Flame Photometer

- Autoclave

- Hot Air Oven

- Digital Conductivity meter

- Digital pH Meter

|

| 6 |

List of Software’s |

|

| 7 |

Practical’s Conducted in Laboratory |

Water Supply Engineering

- Determination of pH of various samples such as drinking water, prepared acidic and alkaline samples, other samples such as soft drink / tea etc

- Determination of Alkalinity of raw water and other samples such as prepared sample, soft drinks and tea etc.

- Total hardness and its components in raw water.

- Determination of chlorides in water

- Determination of chlorine demand and residual chlorine.

- Determination of turbidity and optimum dose of alum.

- Determination of sodium or potassium or calcium using flame photometer.

- Determination of fluorides or iron contents in water

- Determination of Most Probable Number (MPN)

Waste Water Engineering

- Determination of dissolved oxygen in a given water and wastewater sample

- Determination of Bio-Chemical Oxygen Demand in a given wastewater sample

- Determination of Chemical Oxygen Demand in a given wastewater sample

- Determination of solids -Total solids, suspended solids, volatile solids, settleable solids and non-settleable solids in a given wastewater sample

- Determination of Sludge Volume Index in a given wastewater sample

- Determination of Electrical Conductivity in a given wastewater sample

- Determination of Phosphates by spectrophotometer in a given wastewater sample

- Determination of Nitrates by spectrophotometer in a given wastewater sample

|

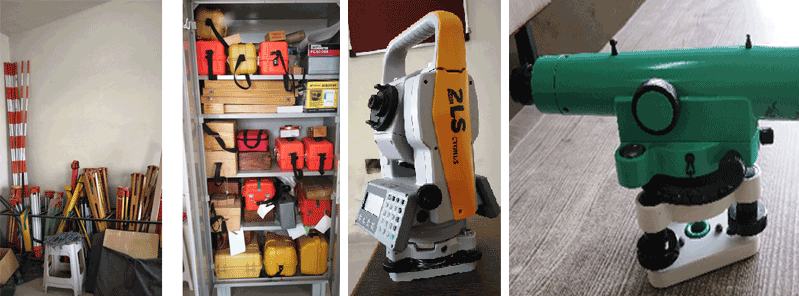

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

75 Sq.Mtr. |

| 2 |

Lab In charge |

Prof. Naik C.V. |

| 3 |

Lab Technician |

|

| 4 |

Lab Investment |

7,48,164 |

| 5 |

List of major equipments |

- Total Station

- LASER level

- 1’’Theodolite

- GPS

- Auto level

- Digital Planimeter

- Nautical Sextant

|

| 6 |

List of Software’s |

|

| 7 |

Practical’s Conducted in Laboratory |

- Measurement of magnetic bearings of sides of a triangle or quadrilateral, correction for local attraction and calculations of true bearings using prismatic compass.

- Plane table survey consisting of both Radiation and Intersection method. Actual mapping of small structure like an area map from central commanding area / small building using combination of both methods.

- Finding horizontal distance and vertical elevation using a Tacheometer.

- Simple and differential levelling with at least three change points using digital level.

- Measurement of horizontal angles (by repetition method) and vertical angles using 1” and 20” Vernier Transit Theodolite. Setting the required horizontal and vertical angles

- Setting out a circular curve by Rankine’s method of deflection angles.

- Setting out a building from a given foundation plan (minimum six co-ordinates)

- Study and use of nautical sextant and measurement of horizontal angles

- Study of the instruments used in hydrographic surveying.

- Practical based on various special functions available in a total station such as remote elevation measurements, remote distance measurements and co-ordinate stakeout.

|

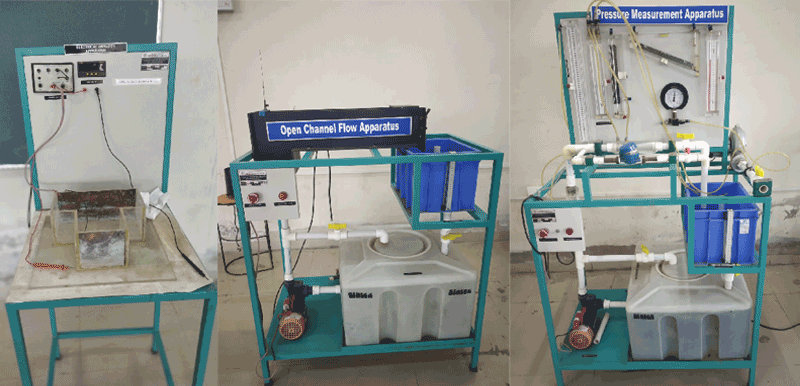

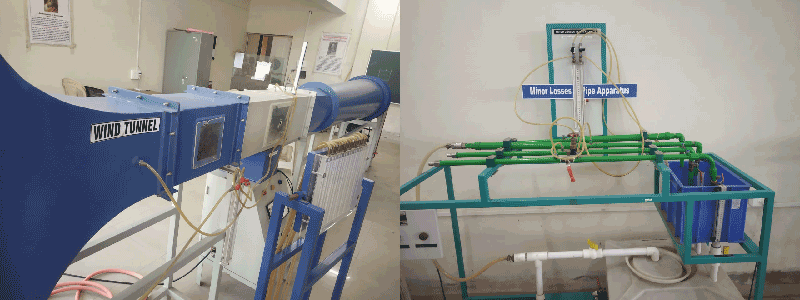

Lab Name: Fluid Mechanics Lab

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

90sqm |

| 2 |

Lab In charge |

Prof. Kate D.B. |

| 3 |

Lab Technician |

|

| 4 |

Lab Investment |

7,95,500 |

| 5 |

List of major equipments |

- Wind tunnel

- Tilting flume

- Darcy Friction factor apparatus

- Combine flow apparatus

- Electrical Analogy

|

| 6 |

List of Software’s |

|

| 7 |

Practical’s Conducted in Laboratory |

- Measurement of viscosity of fluid by Redwood/Saybolt viscometer.

- Experimental verification of Bernoulli’s theorem with reference to loss of energy.

- Calibration of Venturimeter / Orifice meter.

- Determination of Darcy-Weisbach friction factor (f) for a given pipe and study of variation of f with Reynolds Number (Re).

- Flow around a Circular Cylinder/Aerofoil

- Study of Uniform Flow Formulae for Open channel.

- Velocity Distribution in Open Channel Flow

- Calibration of Rectangular and Triangular Notch.

- Determination of Stability of Floating Bodies using Ship Model

- Drawing Flow net by Electrical Analogy for flow below Weir (with & without sheet pile)

- Measurement of Pressure using different Pressure Measuring Devices (including Transducers /state of arts Digital Instruments also).

- Measurement of Surface Tension.

- Determination of Minor Losses in Pipes

|

Lab Name: Engineering Mechanics

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

90sqm |

| 2 |

Lab In charge |

Prof.Atkari K.S. |

| 3 |

Lab Technician |

|

| 4 |

Lab Investment |

20,790 |

| 5 |

List of major equipments |

Universal force table, friction test apparatus |

| 6 |

List of Software’s |

|

| 7 |

Practical’s Conducted in Laboratory |

- Verification of law of parallelogram of forces/polygon of forces.

- To determine support reaction of simple/compound beams.

- Determination of coefficient friction of belt/inclined plane.

- To determine forces in the members of space force system.

- To study the curvilinear motion.

- Determination of coefficient of restitution.

|

Lab Name: Engineering Geology

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

90sqm |

| 2 |

Lab In charge |

Prof.Atkari K.S. |

| 3 |

Lab Technician |

|

| 4 |

Lab Investment |

49,725 |

| 5 |

List of major equipments |

Rocks & Mineral Specimen |

| 6 |

List of Software’s |

|

| 7 |

Practical’s Conducted in Laboratory |

- Megascopic identification of following mineral specimens (around 50).

- Megascopic identification of following different rock specimens. (Around 50).

|

Lab Details

| Sr. No. |

Name |

Details |

| 1 |

Lab Area |

90sqm |

| 2 |

Lab In charge |

Prof.Atkari K.S. |

| 3 |

Lab Technician |

|

| 4 |

Lab Investment |

4,23,574 |

| 5 |

List of major equipment’s. |

DELL DESKTOP, HP Commercial Business Desktop pro 280 G9 MT Chipset 8GB=2x 4GB 1TB NVME slot M2 Tower Cabinet / Serial Part etc.Printer EPSON M100 Ink Jet. |

| 6 |

List of Software’s |

AutoCad , Akses2020 RCBD software etc. |