Infrastructure & Laboratories

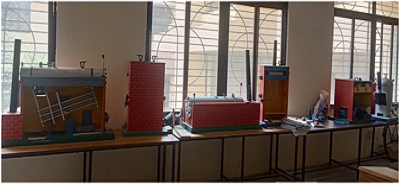

Lab Name: Basic Mechanical Engineering

Lab Details

| Sr No. |

Name |

Details |

| 1. |

Lab Area |

79 Square meter |

| 2. |

Lab In charge |

Prof. Bhagat. S. N |

| 3. |

Lab Technician |

Mr. Holkar N. K. |

| 4. |

Lab Investment |

124610.79 |

| 5. |

List of major equipment |

Models of Boilers Working model of window air-conditioner, Models of bearings, Models of couplings |

| 6. |

List of Software’s |

-- |

| 7. |

Practical’s Conducted in Laboratory |

- Demonstration of vehicle system( 2 stroke, 4 stroke engine)

- Demonstration of boiler mountings and different types of boiler

- Demonstration of household devices(Refrigerator, Water cooler)

|

Lab Details

| Sr No. |

Name |

Details |

| 1 |

Lab Area |

89 Square meter |

| 2 |

Lab In charge |

Prof. Choure. V. S |

| 3. |

Lab Technician |

Mr.Holkar N.K. |

| 4 |

Lab Investment |

833364/ |

| 5 |

List of major equipment |

Thermal Conductivity of Insulating Powder Thermal Conductivity of Composite Walls,Natural Convection Apparatus, Forced Convection Apparatus.

Refrigeration Cycle Test Rig

ICE plant Test Rig

Air Conditioning Test Rig

Window Air Conditioner Test Rig |

| 6 |

List of Software's |

|

| 7 |

Practical's Conducted in Laboratory |

- Practical's Conducted in Laboratory

- Test on vapour compression test rig

- Test on air conditioning test rig

- Test on ice plant test rig

- Test on heat pump test ring

- Test/visit on vapour absorption refrigeration test reg

- Determination of thermal Conductivity of metal rod

- Determination of heat transfer ceofficient in forced Convection.

- Determination of Emissivity of a Test surface

- Determination of Stefan Boltzmann Constant

|

Lab Name: Theory of Machine and Dynamics

Lab Details

| Sr No. |

Name |

Details |

| 1. |

Lab Area |

89 Square meter |

| 2. |

Lab In charge |

Dr. Gawade S. R. |

| 3. |

Lab Technician |

Mr. Holkar N. K. |

| 4. |

Lab Investment |

270931- |

| 5. |

List of major equipments |

Cam analysis machine, Epicyclic gear train apparatus , Generation of gear teeth profile, Four bar chain mechanism, Double slider crank mechanism. Single slider crank mechanism Universal Vibration Lab, Whirling of Shaft apparatus |

| 6. |

List of Software’s |

- |

| 7. |

Practical’s Conducted in Laboratory |

Generation of involute gear tooth profile. Verify Gyroscopic Principles. Verify cam jump phenomenon. Measure the holding torque of epicyclic gear train. Measure the MMI of bar and circular disc by Bifilar and Trifilar suspension. Demonstration of Mechanisms. To determine the natural frequency of damped vibration of single degree freedom system and to find it‘s damping coefficient. To obtain frequency response curves of single degree freedom system of vibration for different amount of damping. To verify natural frequency of torsional vibration of two rotor system and position of node. |

Lab Name: Measurement and Testing

Lab Details

| Sr No. |

Name |

Details |

| 1. |

Lab Area |

89 Square feet |

| 2. |

Lab In charge |

prof. Pondkule S. M. |

| 3. |

Lab Technician |

Mr. Holkar N. K. |

| 4. |

Lab Investment |

472000- |

| 5. |

List of major equipments |

Standard Sample of Metallurgical Structure, Binocular Upright Metallurgical Microscope: Coaxial Body Jominy End Quench Hardenability Setup with Muffle Furnace |

| 6. |

List of Software’s |

- |

| 7. |

Practical’s Conducted in Laboratory |

- Study & Demonstration of Specimen Preparation for microscopic examination.

- Study and Drawing of Microstructure of Steels of various compositions.

- Jominy End Quench Test for hardenability.

- Impact Test

- Vickers Hardness Test

|

Lab Details

| Sr No. |

Name |

Details |

| 1. |

Lab Area |

89 Square feet |

| 2. |

Lab In charge |

Prof. Bhagat S. N. |

| 3. |

Lab Technician |

Mr. Holkar N. K. |

| 4. |

Lab Investment |

207000- |

| 5. |

List of major equipments |

Bomb Calorimeter Cleawl and Flash Point Apparatus, Cloud Power Point Apparatus. |

| 6. |

List of Software’s |

- |

| 7. |

Practical’s Conducted in Laboratory |

|

Lab Name: Fluid Mechanics

Lab Details

| Sr No. |

Name |

Details |

| 1. |

Lab Area |

89 Square feet |

| 2. |

Lab In charge |

Prof. Bhosale K. M. |

| 3. |

Lab Technician |

Mr. Holkar N. K. |

| 4. |

Lab Investment |

|

| 5. |

List of major equipments |

|

| 6. |

List of Software’s |

- |

| 7. |

Practical’s Conducted in Laboratory |

|

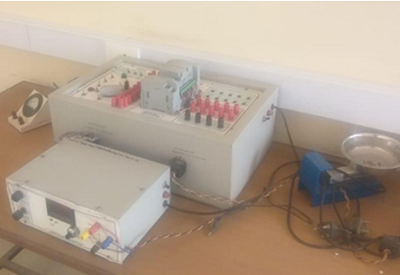

Lab Name: Mechatronics and Automation

Lab Details

| Sr No. |

Name |

Details |

| 1. |

Lab Area |

66 Square Meter |

| 2. |

Lab In charge |

Prof. Sorate S. B. |

| 3. |

Lab Technician |

Mr. Holkar N. K. |

| 4. |

Lab Investment |

146700/- |

| 5. |

List of major equipments |

Measurement of Force/Load using load cell-Load cell trainer, Measurement of Displacement (LVDT haracteristics) LVDT Kit, PLC programing software & Bottle filling & PLC micrologix 1400 |

| 6. |

List of Software’s |

- |

| 7. |

Practical’s Conducted in Laboratory |

- Measurement of Load / Force using a suitable sensor

- Measurement of Temperature using a suitable sensor

- Real time control of Temperature/ Flow using PID control

|

Lab Details

| Sr No. |

Name |

Details |

| 1. |

Lab Area |

66 Square feet |

| 2. |

Lab In charge |

Prof. Kamble S. G. |

| 3. |

Lab Technician |

|

| 4. |

Lab Investment |

Rs. 1172562 |

| 5. |

List of major equipments |

Dell Computer-2.93 GHz Processor, 320 GB HDD, 4 GB DDR |

| 6. |

List of Software’s |

- Autocad

- Creo

- ANSYS

- Mastercam

- Matlab

|

| 7. |

Practical’s Conducted in Laboratory |

- Solid & Surface modeling for simple mechanical components (Output file as Production drawing and Model Based Definition (MBD)

- Assembly Modeling by importing parts/components from free online resources like CAD and Product development software websites, forums, blogs, etc.

- Program on Roots of Equation

- Program on Simultaneous Equations

- Program on Curve Fitting using Least square technique

- Stress and deflection analysis of any Mechanical Component using FEA software and validate the results by analytical methods

- Tool path generation and simulation for Turning – Grooving and Threading with help of suitable software.

- Computer programs for (i) modal analysis and, (ii) stress analysis for 1-D beam (simply supported or cantilever beams)

- Computer program for 1-D temperature analysis

|

Lab Details

| Sr No. |

Name |

Details |

| 1. |

Lab Area |

|

| 2. |

Lab In charge |

Prof. Kamble S. G. |

| 3. |

Lab Technician |

Mr.Shaikh R. J |

| 4. |

Lab Investment |

|

| 5. |

List of major equipments |

Lathe machines, Horizontal Milling machine, Drilling machine, Grinding wheel, Wooden lathe machine |

| 6. |

List of Software’s |

|

| 7. |

Practical’s Conducted in Laboratory |

|